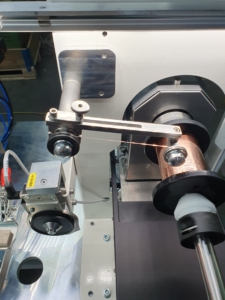

Ultrafine wire drawing machine with inline rolling mill

Schmidt machines are known for their excellent quality and durability. The sturdy machine housings are also able to support additional attachments without any problems. As an example, here is a special application of the ultra-fine drawing machine E10, with which wire in the diameter range from 10µm to 50µm can be drawn and then formed into a flat strip in an integrated rolling mill.

For this purpose, a mill from Roder Engineering in Switzerland was mounted on the drawing machine and combined with an ultra-fine spooler from the SM36 series. The manufacturing process can be done in three ways:

- Wire drawing only and spooling onto cylindrical or biconical spools

- wire drawing with downstream inline rolling and spooling of the flat wire onto cylindrical spools

- only wire pay-off from the drawing machine for flat wire rolling and rewinding

The spooler for the flat wire after the roller is a traversing spool type, and the controoled spooling tension can be adjusted in the range of 3 to 30 cN. This highly sensitive spooler operates without dancers, to reduce the number of deflection wheels. The entire system offers extremely flexible use for a wide range of wire and flat strip variations.

With the use of the latest drive technology, the drawing of high-quality special wires becomes a success. The ES355 slipless drawing machine does not require dancers, resulting in a minimum draw-in length and short set-up time. Wires from 0.5 mm to 5.0 mm are drawn with highest surface quality at speeds up to 6 m/s. Drawing dies from 0 – 21% elongation can be used. The variable adaptation of the drawing steps to the drawing die inserts makes optimum use of the drive power. Thus, the best drawing die sequence can be used for each wire material.

With the use of the latest drive technology, the drawing of high-quality special wires becomes a success. The ES355 slipless drawing machine does not require dancers, resulting in a minimum draw-in length and short set-up time. Wires from 0.5 mm to 5.0 mm are drawn with highest surface quality at speeds up to 6 m/s. Drawing dies from 0 – 21% elongation can be used. The variable adaptation of the drawing steps to the drawing die inserts makes optimum use of the drive power. Thus, the best drawing die sequence can be used for each wire material.