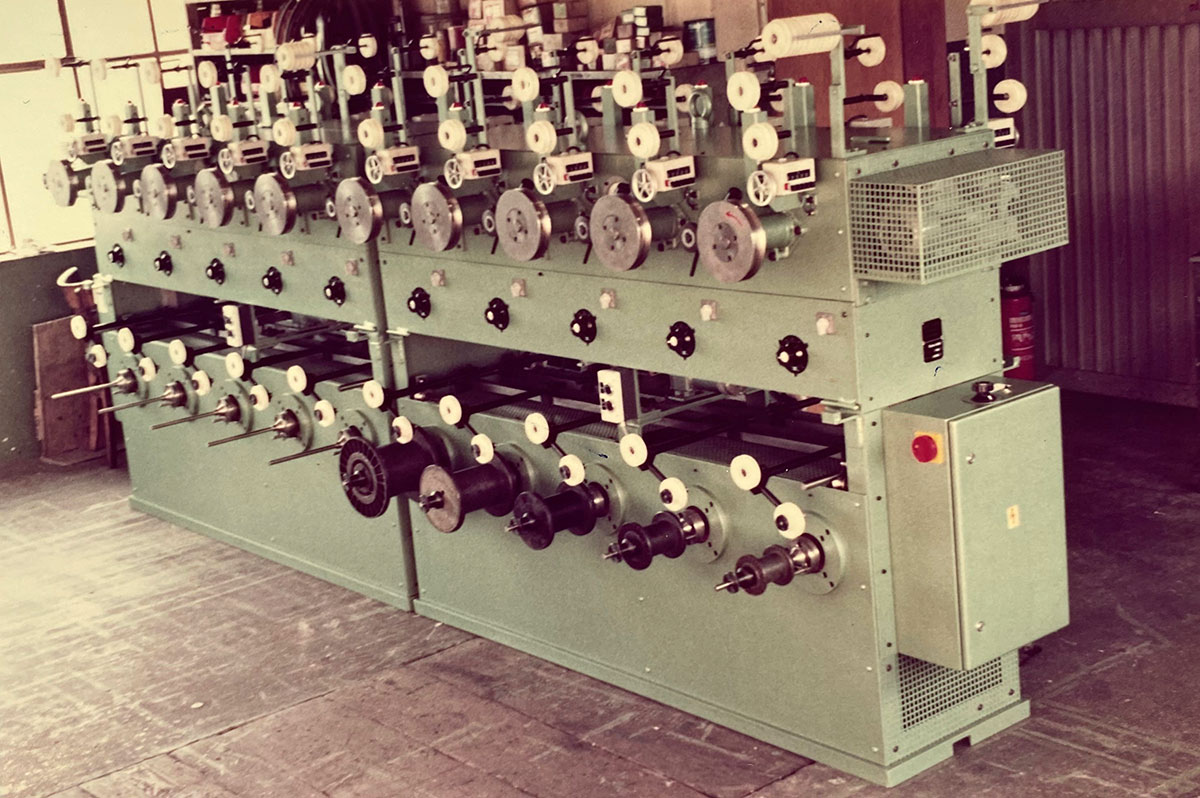

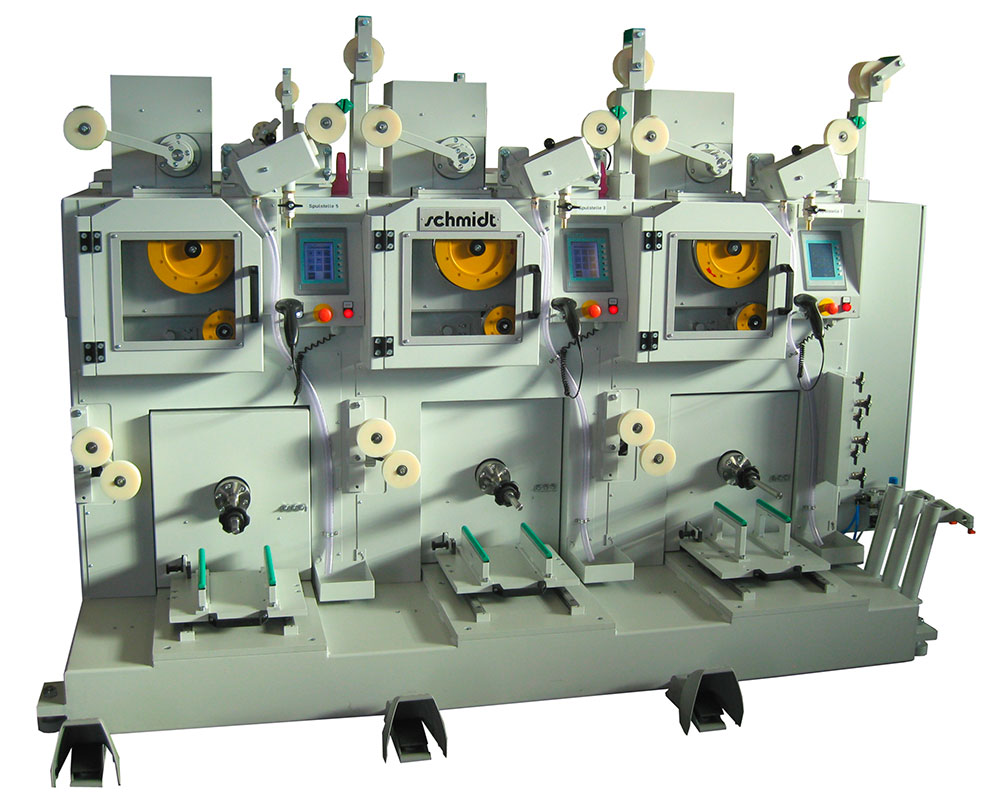

For the annealing processes following wire drawing, Schmidt has been offering winding systems that have been tried and tested for decades. The ever-increasing demands on the winding quality presented Schmidt with the challenge of developing and integrating highly intelligent systems in the smallest of spaces. The result is the annealing take up series SM, which uniquely combines precision in winding with minimal space requirements. In addition, the winding units have bus-compatible controls that make all relevant data available on a central terminal. This means that quality documentation in the form of historical data and trend displays are also available. Industry 4.0 is no longer a future vision but can become a reality.

PERFORMANCE CHARACTERISTICS

- Traversing coil for the best laying quality (low-twist laying)

- Winding tension measurement and control for monitored product quality

- Monitoring of all control parameters, with recording of historical data for quality control

- Modular design, each line with its own control and operation, for maximum system safety

- Optimized design with few wire deflections

- Low energy consumption through the use of modern 24 V / 48 V technology

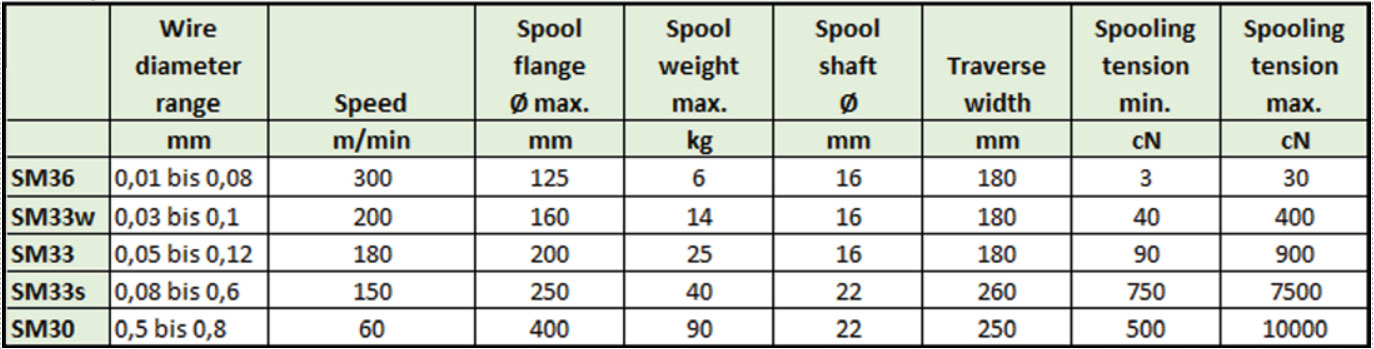

- Versions adapted to the respective wire diameter and coil range

A calibration die is often necessary for larger wire diameters. For this purpose, the take up unit is equipped with a drawing die holder that produces the required calibration in one operation. Robust and compact design are important here. These systems are also combined with traversing winders for the best winding quality.

Spool diameters of up to 800 mm are possible for these machines.

Flat belts require special attention when winding. Know-how and experience are required. Schmidt flat wire winders can also be equipped with laser light barriers to ensure that the winding is successful.