For even more sophisticated wire products, Schmidt offers not only the step-cone and multi-capstan wire drawing machines (wire drawing with slip) but also machines for non-slip wire drawing. Non-slip wire drawing is characterized by the fact that there is no relative movement between the wire and the drawing capstan, so the wire speed and the peripheral speed of the drawing capstans are the same. This lack of slip enables perfect wire surfaces, which are necessary for very special applications. The characteristic feature of our non-slip drawing machines are individually driven drawing capstans that are decoupled by dancers.

Benefits:

- Automatic adjustment of the speeds of the individual drawing capstan to the actual elongation of the drawing dies and thus reduction of the slip to a physically possible minimum.

- Free selection of the drawing die elongation

- Flexibility of the drawing die inserts so that they can be optimally adapted to the material flow properties

- Extended life time of the drawing dies

- Opportunities to increase productivity through higher drawing speeds

- Optimization of the surface quality

Sprayed version

Sprayed versions are used for fine wire dimensions.

We manufacture these to a modular design. In this way, the customer himself determines the number of drawing modules required and can choose from an extensive range of unwinding and winding modules.

The type WDM 100 is characterized by air-cooled drawing disks Ø100mm, they are specially profiled, so that the elastic relaxation of the wire is optimized to reduce slip. The max. Wire inlet diameter is 0.5 mm and the min. Finished wire diameter 0.02 mm.

The type WDM 160 is characterized by water-cooled drawing disks Ø160 mm, which are also specially profiled. The max. Wire inlet diameter is 1.5 mm and the min. finished wire diameter 0.15 mm.

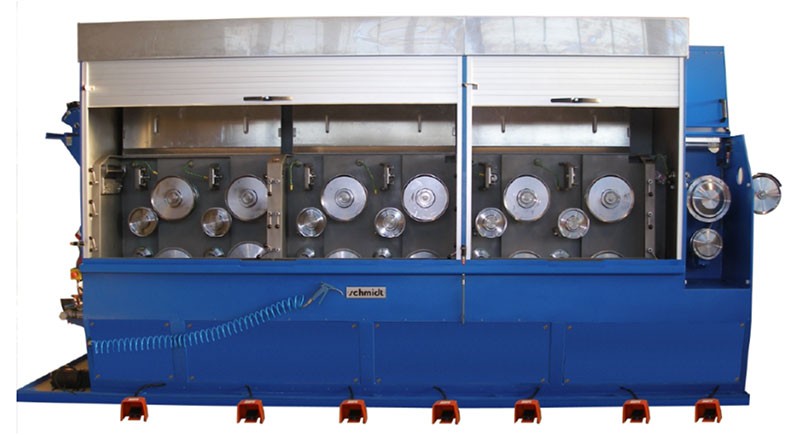

Immersed versions

For thicker wire dimensions we deliver an immersed version of the slipless drawing machine. The wire and the drawing tools are located in a fully submerged drawing chamber and are optimally supplied with lubricant to ensure the best possible cooling.. The number of wire guidance pulleys within the drawing chamber is reduced to a minimum and the wire drawing process takes place without counter-bending and lateral deflection. Each die holder is gimbal-adjustable. In addition to the submerged process, the drawing dies are sprayed with high pressure in order to flush residues.

We deliver the type 5 × 200-40 with capstans Ø250 mm for max. Wire inlet diameter 2.0 mm on 0.7 – 1.4 mm finished wire.

In addition, we manufacture the type 7 × 300-50 with capstans Ø300 mm for drawing max. wire inlet diameter 3.0 mm to a finished size of 0.7 – 2.0 mm.

All our drawing machines that are to be operated with water-based emulsions are manufactured entirely from stainless steel.